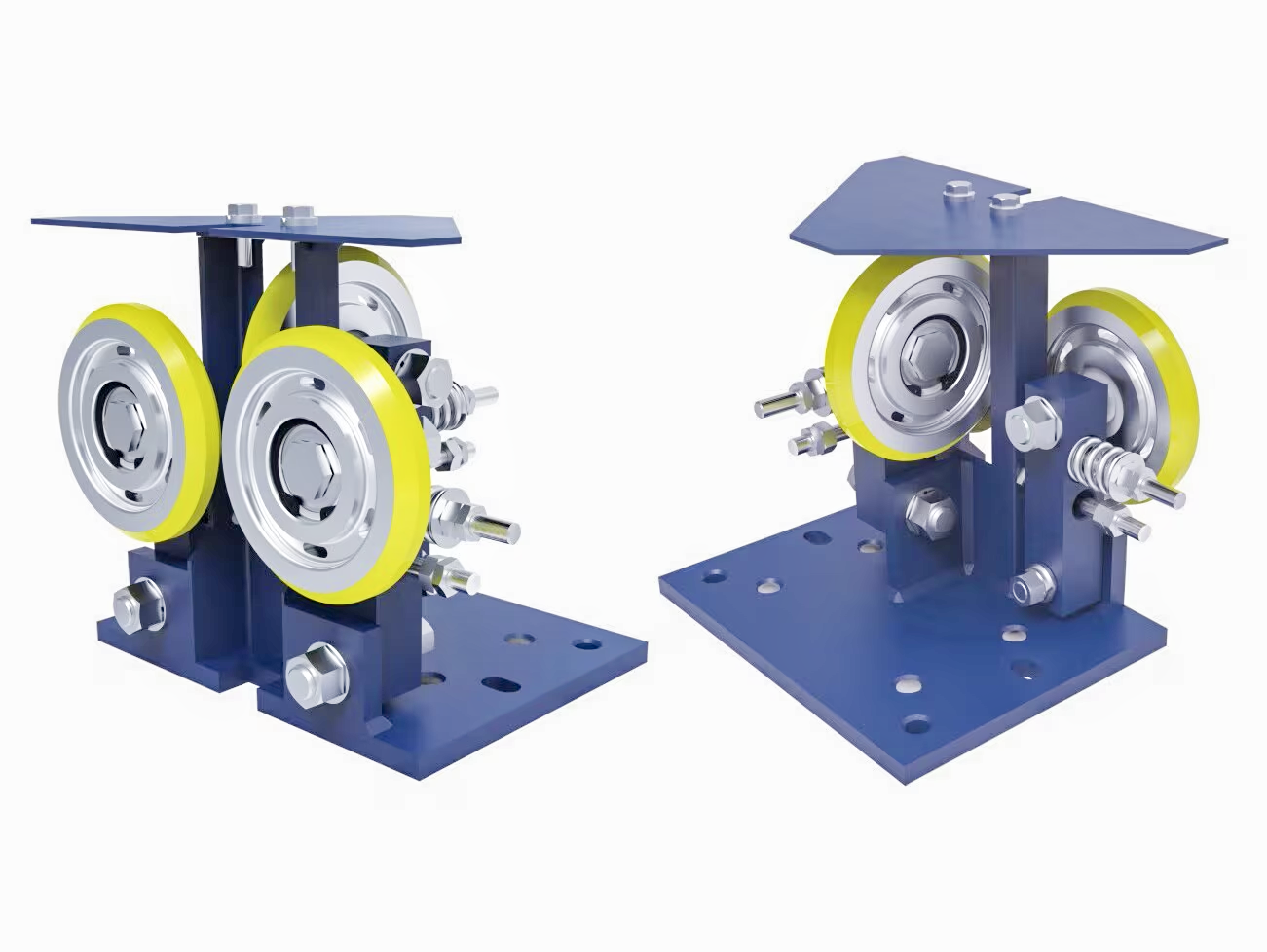

Elevator Rollers

Requirements

of Rollers for Lift Systems:

Material

Strength: Rollers for lift systems must be constructed from

durable materials such as high-grade steel or heavy-duty plastics. The material

strength ensures that the rollers can withstand the weight and stress of the

lift operation without deformation or failure.

Smooth

Surface: The rollers should have a smooth surface finish to

reduce friction and ensure smooth movement along the guide rails. A smooth

surface minimizes wear on the rollers and the guide rails, contributing to the

longevity of the lift system.

Precision

Bearings: High-quality rollers should be equipped with precision

bearings that facilitate smooth rotation and movement. Precision bearings

reduce resistance, improve efficiency, and enhance the overall performance of

the lift system.

Load

Capacity: Rollers must have a specified load capacity suitable for

the weight requirements of the lift system. Properly rated rollers ensure safe

and efficient operation, preventing premature wear and potential safety

hazards.

Corrosion

Resistance: Lift systems are exposed to varying

environmental conditions, so rollers should have corrosion-resistant properties

to prevent rust and deterioration. Corrosion resistance prolongs the lifespan

of the rollers and contributes to the overall reliability of the lift system.

Functions

of Rollers in Lift Systems:

Smooth

Movement: Rollers are essential components that facilitate the

smooth movement of the lift car along the guide rails. They reduce friction

between the lift car and the rails, ensuring quiet and efficient operation of

the lift system.

Support

Weight: Rollers support the weight of the lift car and its

occupants as they move up and down the shaft. Properly functioning rollers

distribute the weight evenly, reducing stress on the guide rails and ensuring

safe operation.

Alignment

Maintenance: Rollers help maintain the alignment of the

lift car within the shaft, preventing swaying or misalignment during operation.

Proper alignment ensures smooth travel and reduces wear on the guide rails and

other components.

Noise

Reduction: Well-maintained rollers contribute to noise

reduction in the lift system by minimizing friction and vibrations during

movement. Noise reduction enhances the comfort of passengers and improves the

overall user experience.

Enhanced

Safety: By providing stable support and smooth movement, rollers

play a crucial role in ensuring the safety of the lift system. Properly

functioning rollers reduce the risk of malfunctions and ensure reliable

operation in various conditions.

By offering detailed

information on the requirements and functions of rollers for lift systems on

the spare parts page of Lofty Elevator Limited's website, customers can make

informed decisions when selecting replacement rollers. Understanding the

importance of high-quality rollers that meet specific requirements will enable

customers to maintain their lift systems' smooth and safe operation. Lofty

Elevator Limited's commitment to providing quality spare parts, including

rollers, will help customers enhance the performance and longevity of their

lift systems.

}})